|

|

Anti-roll

suspension

|

| Between

February 1955 - barely six months after the launch

of the DS

-

and November 1968, six DS were successively fitted

with anti-roll

suspension systems and covered more than 6 000

km. The studies

were intended to improve on both comfort and

roadholding (neither of

which could hardly be called bad!) compared to the

production car. |

|

|

|

| The

two pictures above demonstrate the system in

action - the car on the

left is a normal production vehicle, the one on

the right is fitted

with antiroll - same bend, same speed. The

picture on the right

gives little indication of the speed - until you

notice how the left

front tyre is deformed.

The

system could have been put into production in

the late sixties but the

team was forced to abandon its research to

concentrate on the

soon-to-be launched GS.

A prototype

SM with

zero roll suspension was also developed in 1973.

Paul

Magès had intended such a system to be part of

the design of the

suspension system and as early as 1944, he had

sketched just such a

system, a derivation of which was fitted to a prototype 2CV

in 1946.

|

|

It was not

until the launch of the Xantia

Activa

below that such a system was put into

production

|

ELECTRONIC

DATA

1 Steering wheel angle

2 Rate of steering wheel rotation

3 Vehicle velocity

A High pressure pump

B Anti roll regulator

C Electro valve

D Regulator

E Activa accumulator

F Front stabiliser cylinder

G Rear stabiliser cylinder

H Stabiliser

I Suspension computer

|

|

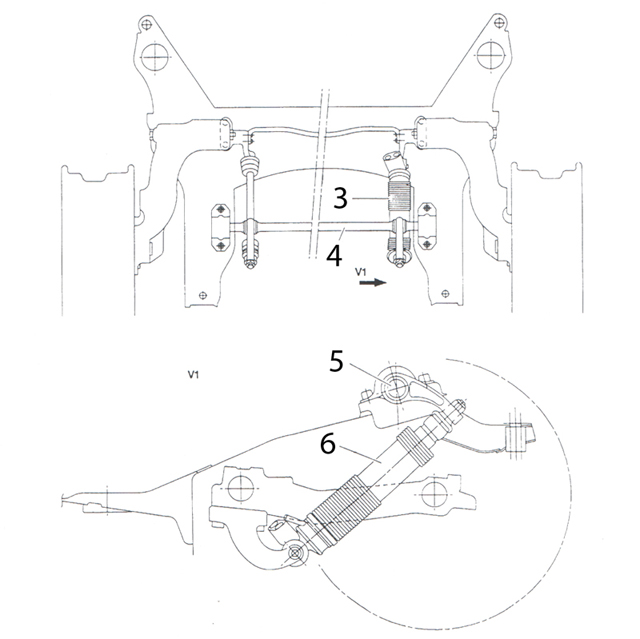

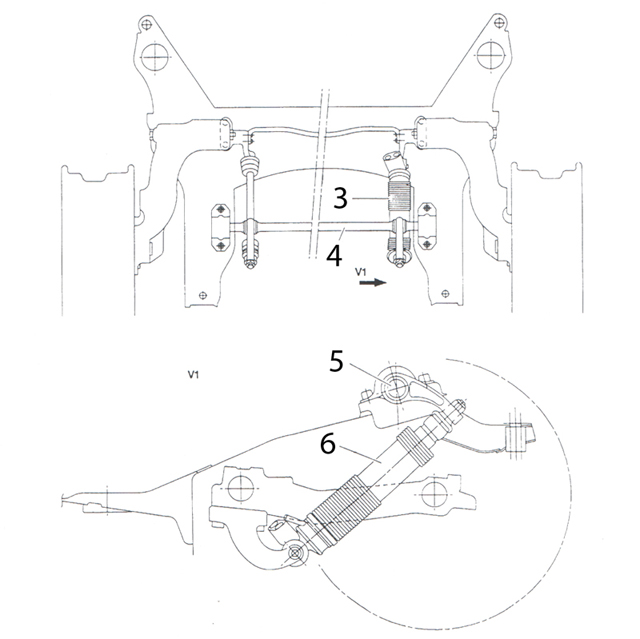

FRONT

SUSPENSION

MECHANICAL LAYOUT

1. Front stabiliser bar

2. Front stabiliser (anti-roll) bar

|

|

REAR

SUSPENSION

MECHANICAL LAYOUT

3. Rear stabiliser cylinder

(hydraulic ram)

4. Rear stabiliser (anti-roll) bar

5. Rear stabiliser (anti-roll) bar

6. Rear stabiliser cylinder

(hydraulic ram)

|

|

Other

developments

|

|

|

Electro-hydraulic

gearbox

Anti-roll

suspension was not the only project

being developed by Paul Magès'

team. Amongst the ideas being

contemplated were electro-hydraulic

control of the gearbox which employed

electronics to change gear,

making use of the following parameters:

vehicle speed, engine speed,

throttle depression and rate of throttle

movement. The result was

an improvement of 10% in economy and

improved performance. This

project never made it into production. |

|

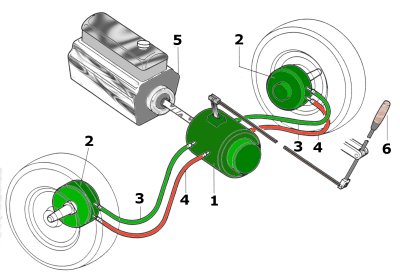

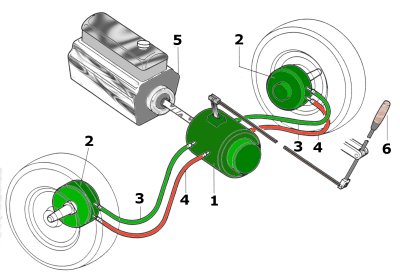

Hydrostatic

transmission

Hydrostatic

transmission was yet another idea that

was abandoned. As early

as1908, Louis Renault had proposed just

such a system. The idea

is relatively simple; the engine drives

a pump which sends fluid under

pressure to four hydraulic pumps in each

wheel hub. There is no

need for different gear ratios and

transmission is therefore

continuous, the clutch being dispensed

with also. Furthermore

there was no need for a separate braking

system. Magès and his

colleagues worked on this project for

twenty eight years and some

thirty prototypes were fitted with the

system (2 CVs, GSs and a CX)

between 1958 and 1973 and covered a

total distance of 1 130 000

km. However there were major

problems with noise and when Peugeot

took control in 1974, the project was

killed off. Hydrostatic

transmissions are used in vehicles such

as forklift trucks and some

specialist earth moving vehicles. |

1.

hydraulic

pump

2. hydraulic motors

3. hydraulic pipes - forward

rotation

4. hydraulic pipes -

backwards rotation

5. conventional engine |

Joystick

steering

Magès

also worked on the project that led to

the DIRAVI steering system -

powered return of the wheel to the

straight ahead position coupled with

both variable ratio (movements around

the straight ahead position

result in small deflections while moving

away from this position

results in larger deflections) and

variable assistance (as velocity

increases, assistance diminishes).

A DS was fitted with a system

which was 100% assisted and the steering

wheel was replaced with an

aircraft type joystick - one steered

with tiny movements of a finger

and with one's eyes. It was felt

that despite the undoubted

advantages such a system would offer

(unrestricted view ofthe

instrument panel and removal of the

injury potential of a wheel and

column), the clients would dislike it. |

Hydraulic

motors

Hydraulic

motors weigh one sixth of an equivalent

electric motor. Since the

DS was already fitted with a high

pressure hydraulic system, it was

logical to look at other applications

including an hydraulically

powered cooling fan

(30% reduction in weight and 30%

reduction in radiator volume, thereby

freeing up some much needed under bonnet

space and allowing the

radiator to be mounted at an angle); hydraulically

powered

windscreen wipers which had much

higher starting torque than

electric ones and could be steplessly

variable in speed; an hydraulically

powered alternator which would

supply power on demand; hydraulically

powered

window lifters, hydraulically

powered starter motor... |

|

|

|

...and probably most

bizarre of all, a roof mounted, hydraulically

powered air brake which

not only employed wind resistance to slow the car

but also increased

the rear wheel downforce thereby reducing the

tendency for the rear

brakes to lock up. As early as the beginning

of the sixties, an anti-lock

braking system had also been perfected. |

|

|

©1999 Julian Marsh |