|

||||||||||||||||||||||

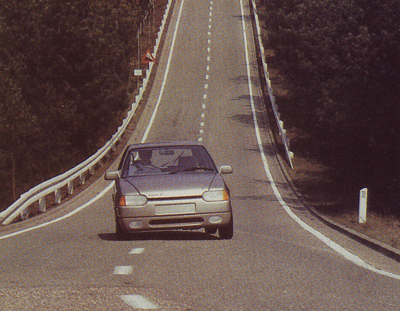

Towards the plastic car |

General Electric Vector |

|

General Electric Plastics is currently working on the development of all types of plastics for industrial uses. Among those uses, the automobile comprises an important part. It is not a vain exercise to provide a variety of materials to produce the multiplicity of parts that are used in our cars. To list these items would be lengthy, since the latest generation of plastics is ever important. To do so the engineers of General Electric have built a vehicle with which to implement their research. It is the GE Vector, which demonstrates the tremendous potential of thermoplastic engineering. This car has been built on the base of a Citroen AX and was carried out by the Center of Automotive Engineers in Bergen-op-Zoom (Netherlands) who own General Electric Plastics. The team was led by Richard McKechnie, director of Design and Engineering. It is not a hand-made prototype, since the parts were manufactured using plastic molds for production thereby proving the feasibility of mass production. In the Vector, the plastic has been used in a number of very important areas such as the body, where most of its panels both external and internal are made of plastic and in the engine with the sump and rocker box. With the use of these materials, the car loses weight and enjoys improved resistance to corrosion and impact, while offering substantial savings in production costs assuming a production run 100,000 units. Put into mass production, the Vector would have an even greater number of parts made of thermoplastic. Vector may well prefigure the cars of the future. General Electric's leaders are convinced that the Vector foreshadows the sort of vehicle that car manufacturers must produce if they are to survive in the future. |

|

|

|

|

|

|

|

Right Project Manager Richard McKechnie promoting the GE Vector by London's Tower Bridge in 1988 © 1998 Press Association. Originally published in the Spanish magazine Motor16 nļ 274 on

21/01/1989 |